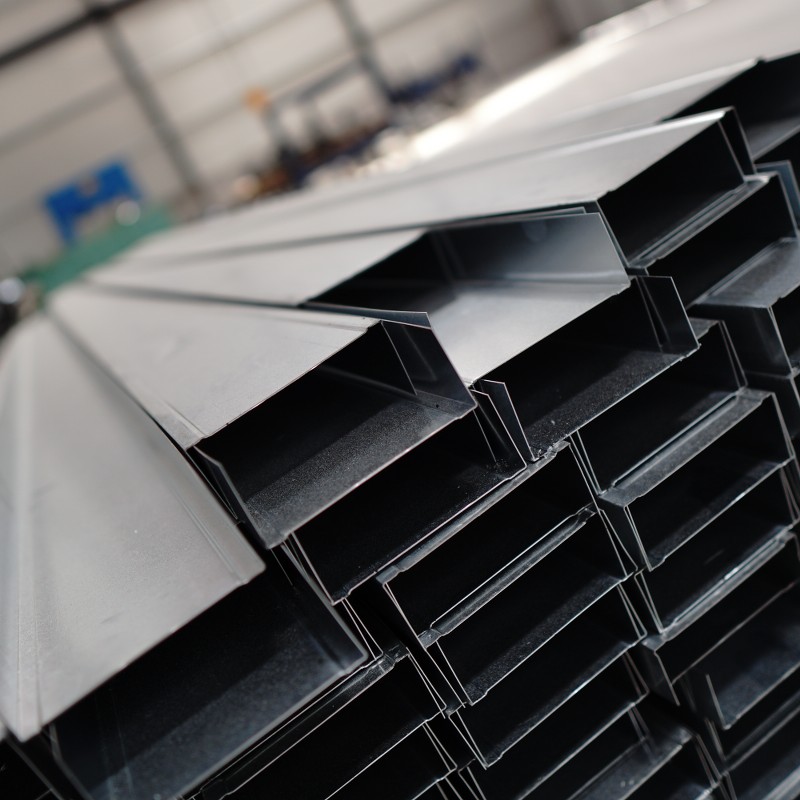

PİPES – HOLLOW SECTİONS PRODUCTİON SCHEME

- Slitting

Steel coils of various thicknesses and grades are slitted into the strips based on the width to be produced. In this way, steel coils are transformed into strips, also called slitted coil, making them suitable for tube and hollow section production.

- Cold Forming

The slit coil of proper dimension prepared for production is passed through the forming rollers to obtain the product with desired final dimensions.

- High Frequency Welding

When the high frequency current passes through the magnetic field surface, it causes heating at the edges. V-shaped open edges are welded through the instrument of pressure rollers.

- Spraying Zinc

After removing the upper burr in the weld area spraying zinc on the joint area.

STEEL TYPES

Galvanised Cold Rolled CoilGalvanized Hot Rolled Coil

Colled Rolled Coil

PRODUCTİON STANDARTS

STANDARTS QUALİTY

PİPES

EN 10305/3 DX51D-DX52D-DX53D-DX54D-DX56D-S220-S250-S280-S320-S350-S390-S420-DC01-DC03-DC04-DC05-DC06HOLLOW SECTİON

EN 10305/5 DX51D-DX52D-DX53D-DX54D-DX56D-S220-S250-S280-S320-S350-S390-S420-DC01-DC03-DC04-DC05-DC06PRODUCTİON RANGE

THİCKNESS BOY / LENGHT

PİPES 21,3 mm – 101,6 mm 0,70 mm – 3,00 mm 3000 mm – 10000 mmHOLLOW SECTİON 20*20 – 80*80 0,70 mm – 3,00 mm 3000 mm – 10000 mm